Vijay Krishnan October 3, 2019

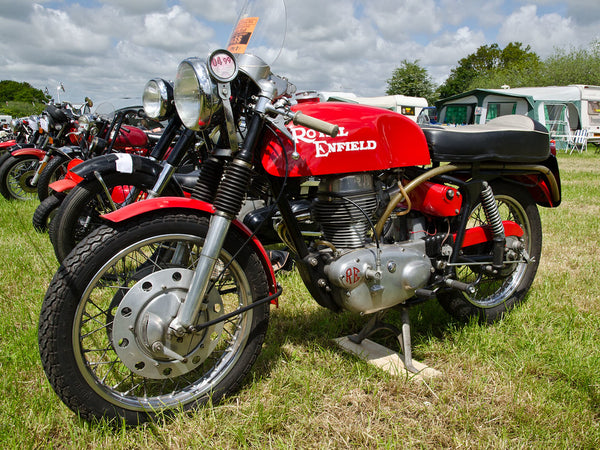

A Cafe Racer was never about practicality. It was purely about shedding as much weight as possible to go as fast as possible, all this while looking good while you are at it. Ask any hardcore fan of retro racers and they would immediately point out to the fairing as an integral part of getting the look right. It was a means to make the motorcycle cut through the air like a missile and go as fast as possible.

The Royal Enfield Continental GT has to be one of the prettiest bike out there. Touted as an old school cafe racer, it is a perfect platform to build the bike and make it your dream spec retro racer. And we have the most important piece of the jigsaw now available as a bolt on option courtesy of J&D Custom Co.

A one man army, Jay D. Patel or JD has now an established name in the custom motorcycle scene. He is the maker of some exquisite cafe racers among other motorcycles and has been featured by the likes of BikeEXIF, Bike Burn, Fast Bikes India and basically every custom Motorcycling magazine.

That takes care of the pedigree behind the making of the new fairing. We talk to JD himself and get to know more about the new fairing and try to better understand what goes into making each one.

Why the fairing?

As a fan of retro racing motorcycles, I was always a stickler for the Cafe Racer. If you take a look at the history of the Continental GT up until the 535 Conti, these bikes were used all around Europe in racing. They were fitted with a fairing and was thrust into endurance races all over Europe. We cannot compare these motorcycle to a super bike but the charm it offers is something else.

Photo Credits - Wikimedia Commons

One thing that people tend to overlook is that apart from adding to the aesthetic appeal of the bike, it makes the bike more aerodynamic. Another benefit of adding a fairing would be the reduction in wind blast. A significant part of rider fatigue comes from being exposed to wind blast all day and a fairing will go a long way in alleviating that stress from your body.

An experienced rider can tuck behind the fairing and protect himself/herself from wind blasts that enables one ride harder and faster without fatigue kicking in. Although I have not put any science into the development of the fairing in terms of wind testing, I have put in enough hours in testing to make sure that the fairing does represent a significant improvement over the stock bike. The fairing helps the bike cut through the air better and a few of my customers have even said that they reached the top speed on their bike with the fairing on.

What goes behind making one of these?

I am the first person in India as far as I know to offer a bolt on kit for the Continental GT 535. Whatever I learnt from my trials and tribulations over the 535 fairing, I have applied it to make the most near perfect kit for the 650. I feel I have hit the nail on the head with this new fairing in terms of overall design and aesthetics. For the 535, I had to make a lot of compromises on the design so as to keep the bike’s usability intact. Things such as the turning radius, ergonomics and making sure no part hits the fairing are tantamount. Also, things that people normally ignore while trying to put on a fairing is keeping the headlight still. The traditional café racer design calls for the headlight to stay still even when the handle is turned. I have to take a lot of such factors into consideration and make the product so that none of the bike's parameters are affected.

I started making the fairings thing in 2016 with the bolt on kit for the Continental GT 535. This was around the time when Royal Enfield was wrapping up production of the GT535 for India. I knew enough about Café Racer fairings but did not know that they came as a bolt on option. It was during this time that a group of Continental GT riders from Kerala approached me with an order for 12 fairings for the bike. They wanted me to make it out of metal initially. So I started my work on the fairing with the prototype and over the years I came out with atleast 4-5 iterations of the 535 fairing. As far as I knew, I was the only one apart from Hitchcocks motorcycle to offer a bolt on fairing for the GT 535.

So when the 650 got launched in Novermber, individuals who booked the bike and who wanted the classic café racer look started approaching me. I got atleast 5-6 enquiries for the 650 fairing every month. But this time I was determined to sort out all my shortcomings from the previous version for the 535 such as the bracketing, windshield and the overall design.

The most important part of a fairing if you look at it would be the side profile. I’ve taken extra measures to make sure the fairing looks spot on from nearly every angle and still retain the same ride ability of the stock bike.

Then comes the situation with the fairing windshield. When I initially designed the 535 fairing, I wanted to make the fairing with a proper windshield. For this, I approached a maker of these windshields who had previously worked with Royal Enfield. I was told that the Aluminium moulds needed to form these windshields was very expensive that it would end up costing me at least 10000 per windshield. This blew the idea of using an expert to source these windshields out of the water. So I had to do away with the windshield for the continental GT 535. The entire fairing was made out of fibreglass with the windshield deleted. I did not pursue getting the windshield right as it was not sustainable to put so much effort and money into a motorcycle that was failing in the market.

And when the 650 came out, I saw the immense potential in the bike and I realized that it would be worth putting in so much capital and effort into developing it. This time however, I knew that to make the fairing of my liking, I had to incorporate an authentic retro-style windshield. So I went to work learning the ropes to the process involved in making these windshields which was the Vacuum Forming process. It took about four months to develop the setup needed to churn out the windshield of my liking. I had seen that many manufacturers were doing this process on their Vacuum forming machines in house to forming these fairings.

I developed the fairing on a Continental GT 650 that I borrowed from a local dealer. I used to take the bike from them for the night and return it by day when it was needed for duty as a test ride vehicle. It took about 4-5 such turns with the Continental and about one and a half months of time to get it fully buttoned up.

What people don’t realize about the price factor is that so much work goes into making each fairing. I make everything in-house and each fairing is hand built. Also, I have to make sure they function perfectly on the bike without any vibrations. Added to this is the process of making the fairing as simple as possible to be bolted on to the stock bike with minimal modifications.

What has to be done to bolt the fairing onto the bike?

The fairing can be installed by anyone with some engineering accumen as a DYI operation as there is no need of making way for accommodating the kit. All one needs is to relocate the turn signals and lower the handles by an inch to accommodate the fairing. This is so that the bike can be turned without the handlebar clashing with the fairing. I will, of course, be providing all the necessary mounts and brackets to accommodate the kit on the stock bike.

Learn more on how to install the fairing here.

In what colours are the fairings available?

As for colours, I offer them in black and white with a view that the black would go with the Mr. Clean, Black Magic and Dr. Mayhem paint schemes and the white would integrate into the Ice-Queen colour. As for the Ventura Blue, I would be coming out with the fairing painted to match that colour very soon.

How has the response for the fairing been so far?

So far the response for the fairing has been so far overwhelming. I have orders pending and I’m thinking a lot of people are waiting to see how the fairing looks on the bike from what my customers post about them before pulling the trigger.

Where can I buy one?

Check out the all new fairing here

Check out the other awesome JD Custom Co. creations on instagram @jdcustomco

comments

Hi,

Could you give me a price for the fairing in black with delivery to the Isle of Man,United Kingdom.

Regards,Nigel,

can you please give me a price for your fairing and shipping to the uk thank you

And are they made in the red ?

hello can you please give me a price for your fairing and shipping to the uk thank you